One of the most significant advances in yacht safety in recent years has been the development of the Jordan Series Drogue. It was developed in response to the 1979 Fastnet Disaster and has been widely used by a wide variety of yachts in some terrible conditions. Attainable Cruising has many articles about it (and I think some are on their free pages).

So we definitely plan to carry a Jordan Series Drogue with us. Examples from Jordan Series Drogues by AceSails (lots of the history by the late Don Jodan himself), Ocean Brake and DIY instructions from SailRite.

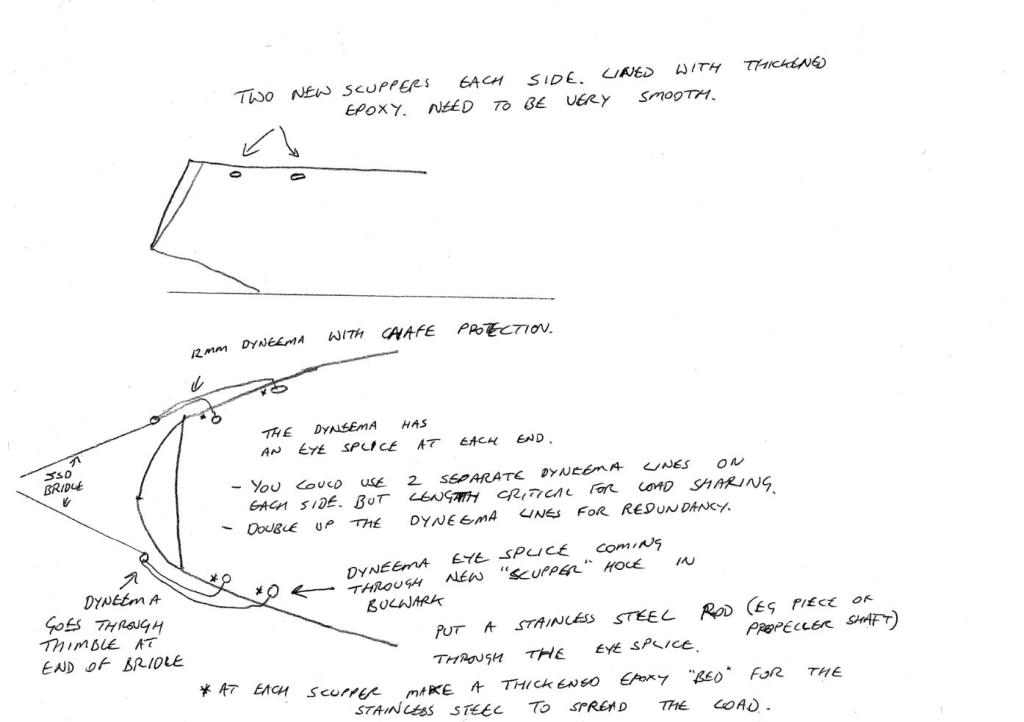

Once you have a JSD (Jordan Series Drogue) one of the key concerns is how top attach it to your boat. The loads could be enormous and so typically the solution has been big stainless steel chainplates through bolted to big backing plates, one on each aft quarter so that they stick out beyond the stern.

That is heavy, and is going to require some substantial engineering (and to be fair John Harries, from Attainable Cruising, admits that he had misunderstood that bolts in a line with the load do not share the load well – something Jane keeps on at me about from her Civil Engineering days).

The chainplate solution would be possible, but expensive and hard work on our boat (the bulwark is the obvious place as it has both the hull and deck thicknesses together) but it isn’t very high so the gap between the cap and the deck is a bit tight for a good sized backing plate.

So I was pondering and I realised that there might be a good solution similar to the Dyneema chainplates we have come up with. After a couple of iterations this is what I have come up with for boats like ours that have a strong enough bulwark or toe rail (essentially the rule of thumb is these need to be strong enough to hang the weight of the boat from). For us the strength of the 12mm dyneema we are likely to use for our main mast shrouds is a lot more than double the design weight of the boat. The issue is much more about spreading that load rather than the strength of the line.

[Update] I have written a lot about Dyneema standing rigging so I now have a guide to it all in: Dyneema / Synthetic Rigging Summary[End Update]

So I’m thinking one 12 mm dyneema line for each side of the boat. Both ends to be fastened to the boat with the loop going through the eye on the end of the JSB bridle. So the load will come to 4 attachment points on the boat and will be pretty equally balanced (the elastic stretch and creep of the dyneema will work to equalise the loads between the two bridles and on each side the loop will move through the bridle loop to equalise the load.).

All 4 ends of dyneema will have an eye splice (carefully done should achieve 80% of the original strength) and the eye will have a chafe protection sleeve as will the loop where it goes through the bridle.

To attach these eye splices to the boat we cut scupper drains holes through the bulwark. These are angled so that the outside is pointing aft. They will need to be very smooth and large enough for the dyneema eyesplice. It might be worth using HDPE tubing. Otherwise I’ll make them oversize, fill them with thickened epoxy and then drill and smooth that.

On the inside of the bulwark we will pass a stainless steel rod (probably similar to our propshaft) through the eye splice and lay it horizontally along the inside of the bulwark as the “backing plate”. To spread the load of the stainless steel rod we would build up thickened epoxy between in and the bulkhead. We will coat the rod in mould release first so that the rod can be removed once the epoxy has set and only placed there when needed.

The length of the stainless steel rods will depend on the curvature and strength of the bulwark or toe rail. If there are concerns then use more and connect the dyneema in a cascade to distribute the load to 4 or more points per side.

This way we get better draining side decks (more scupper holes). We get a JSD attachment system that

- is stored away from UV and other damage except when on ocean passages.

- is easy to fully inspect every part of before use

- can have any part replaced at sea if it shows wear

- doesn’t add permanent clutter or any potential leaks

- is lighter and stronger than a stainless steel chainplate

- is much cheaper than the parts for stainless steel chainplates

Of course there are disadvantages and key among these is the potential for chafe. However, this can be easily monitored and if required a temporary Dyneema line could be used while a replacement is fitted at sea. We are not kidding ourselves that it would be easy but won’t require hanging off the back of the boat and is possible. Whereas making and fitting a replacement stainless steel chainplate would not be.

If your boat doesn’t have a bulwark/toe rail that is suitable then a more permanent solution more like multiples of our various dyneema chainplates idea might be possible.

Almost certainly we will be trying something along these lines, but we do so at our own risk and you would have to do your own risk analysis and design.

[Update] Another “brilliant” sketch of this design.

Leave a comment